Flexible Intermediate Bulk Containers (FIBC) or commonly referred to as bulk bags, offer users many different options when it comes to customizing specifications that fit specific filling requirements. Flexibility of design allows options such as stackable bags, non-sift seams and of course ability to dissipate electrostatic.

Type C Bulk Bag

The Type C bulk bag consists of non–conductive polypropylenes that are woven with conductive materials in a grid–like manner, and this connects the bag to a surface through what is known as the grounding point.

When the bag is used for the purposes of fillings and discharges, this grounding connection is integral to the safety of the Type C bulk bag. Nonetheless, the task of keeping the Type C FIBC interconnected and grounded is sometimes prone to fault when handled manually by staffers at a given facility that uses bags of this type.

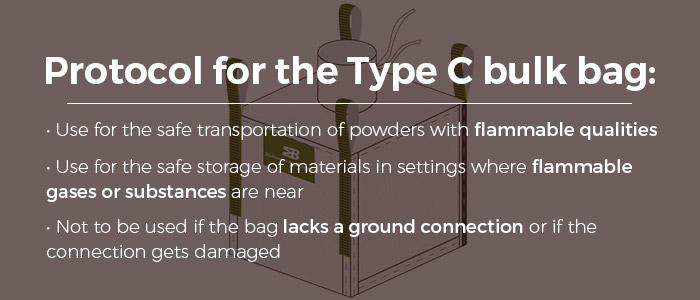

The basic protocol for the Type C bulk bag is as follows:

- Use for the safe transportation of powders with flammable qualities.

- Use for the safe storage of materials in settings where flammable gases or substances are near.

- Not to be used if the bag lacks a ground connection or if the connection gets damaged.

The conductive and non–conductive threads that comprise the panels of a Type C bulk bag are interwoven in grid–like patterns. For the Type C bag to be used safely, it must be connected electrically and connected to its grounding point whenever fillings and discharges take place.

Type D Bulk Bag

The Type D bulk bag consists of a combination of fabrics, some with antistatic qualities and others with static dissipative qualities. Combined, these qualities work to brush discharges and prevent sparks, all without the use of a ground connecting point.

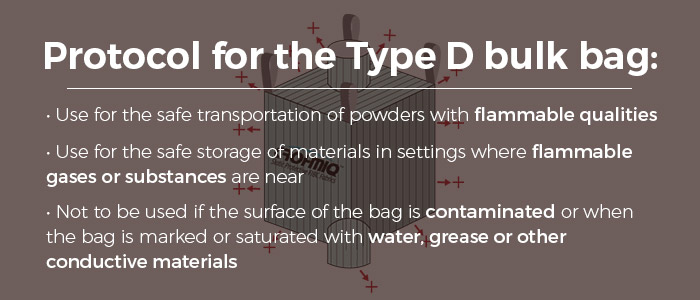

The purpose of the Type D bulk bag is to store combustible products with utmost safety in toxic environments and for the transportation of said products through areas in which flammable substances are present. As such, the purpose of the Type D FIBC can be summarized as follows:

- Use for the safe transportation of powders with flammable qualities.

- Use for the safe storage of materials in settings where flammable gases or substances are near.

- Not to be used if the surface of the bag is contaminated or when the bag is marked or saturated with water, grease or other conductive materials.

Today, CROHMIQ Type D bulk bags are considered the safest of all FIBCs on the market.

Different Types of Electrostatic Discharges

In an electrical field, a lone electrical conductor gains a certain quality along its surface. With this, the conductor sparks a current that lasts until the field runs out. For the free electrons, the field’s positive pole is the natural direction of travel. On the contrary, the opposing side’s excessive charges are held by negative charges, which generate from the field’s opposite pole.

When the charges from one end are cut with a ground connection while the body remains in the field, the body becomes charged once it’s taken out of the field.

The kinds of charges that are liable to happen as the result of the accumulation of electrostatic charge on an FIBC could include any of the following:

- Brush charges, which can stem from the surfaces of FIBCs with standard insulation. In flammable environments, these brush charges are liable to ignite. This ignition requires roughly 3mJ to 5mJ.

- Propagating brush discharges (PBD), which can stem from the surface of an insulated FIBC. This is liable to occur if the surface has an electrical voltage level in excess of 6,000 volts. PBD may cause ignitions in environments where flammable gases, dusts or vapors are present.

- Spark discharges, which can stem from the conductive threads of ungrounded groundable bags, as well as from said threads within the panels of corona FIBCs.

The kinds of discharges that are liable to happen when static charge accumulates on the surface of the powder or within the surroundings of an FIBC may include any of the following:

- Cone discharges — or bulking discharges — which can occur along the top of a powder supply in an FIBC, as well as in the receiving vessel when transfers take place. A cone discharge can set off in flammable environments, where an ignition is liable to occur with 25mJ.

- Brush discharges, which can happen along the top of a powder supply once a transfer has been completed. A brush discharge is capable of causing ignitions in flammable environments. For an ignition to occur, 3mJ to 5mJ would be required.

- Spark discharges, which may occur along the metal parts of a storage system when a transfer of powder takes place. Spark discharges can also occur along the surfaces of conductive products in FIBCs and vessels that insulate. A spark discharge can even happen to an ungrounded person within such an environment.

The potential for damage caused by the preceding charges and discharges makes it imperative to follow safety standards when handling FIBC Type C and D bulk bags.

Basic Methods of FIBC Testing for Specific Applications

For an FIBC in the 0.25m3 to 3m3 range, the following requirements apply if the bag has been designated for use in environments where explosive properties are present.

- The FIBC must be marked with labels and classification indicators to mark its intended use.

- The inner liners must be marked with classification indicators of intended use.

- The testing methods for each FIBC and inner liner in question must be specified.

- The design and performance standards of each FIBC and inner liner in question must be specified.

- Safety standards for each FIBC must be established for each zone in which usage takes place.

- Qualification and certification procedures must be adhered for each FIBC and inner liner.

The preceding requirements are applicable to FIBCs and liners of any type that has been made, tested and intended for environments in which explosive properties are present. The requirements must be implemented before each use. In select settings, the requirements might only apply if the explosive properties hold an ignition energy of 0.14mJ or more and the charging currents top out at Am3.0.

In addition to the proceeding requirements, the full range of potential risk must be evaluated about the substances and environments in question before an FIBC is put into use.

The Classification of FIBCs

FIBCs are divided into four distinct types — Type A, Type B, Type C and Type D. Each different type is distinguished by its construction and the requirements of its intended purpose.

Type A FIBCs consist of panels of either plastic or fabric that lack resistance to electrical static buildup. The Type A bulk bag is not to be used in environments where flammable properties with ≤1,000mJ Minimum Ignition Energy are present.

Type B FIBCs consist of panels of either fabric or plastic that are made to eliminate sparks and brush discharges. The Type B bulk bag is made to be used in dusty atmospheres where >3mJ ignition properties are present, providing that no flammable gases or vapors are in the midst.

Type B bulk bags must be made with materials that possess a ≤6kV electrical breakdown voltage. The requirements for Type B bulk bags must also be applied to any materials — barring mesh or net — that are used for the inner baffles.

Type C Bulk Bag Specifications

Type C FIBCs utilize grounding to override the presence of electrostatic hazards. The Type C bulk bag should either fully consist of conductive material or comprise an interwoven mix of conductive and non–conductive materials. If done in a striped pattern, the threads of the materials used in the panels of a Type C bulk bag should feature spacing of no more than 20mm. If the panels are woven in a grid pattern, the spacing should not exceed 50mm.

Type C bulk bags are made to be used in environments where flammable gases or vapors are present, as well as in settings where combustible dust levels reach MIE ≤3mJ. Type C FIBCs must have a resistance to groundable point 1.0×1012 ohm per Square.

Within four–layer bags that are made of multi–layered materials, the surfaces of both the insides and outsides must have a resistance of under 107 ohm. For layers that lack a ground resistance of under 107 ohm, a breakdown voltage of ≤6kV is required.

The design of a Type C bulk bag depends on grounding for the purpose of electrostatic prevention. On every inch of the FIBC, resistance to groundable point <1×107 ohm is necessary. If a Type C bulk bag is electrically isolated from the ground, the risks of ignition would exceed that of a Type A or Type B bulk bag. The materials that comprise the inner baffles of a Type C FIBC — barring net or mesh — must meet the requirements of the bulk bag type.

Type D Bulk Bag Specifications

Type D bulk bags are made with fabrics that contain properties that manage the incendivity of discharge, as well as threads that protect against static. Type D FIBCs are meant to be used in environments where flammable gases or vapors are in the midst. FIBC Type D classification bags are also made for settings in which MIE ≤3mJ combustible dusts exist.

The material in the paneling of a Type D bulk bag contains a layer of insulation — such as lamination, film or other type of coating — along the insides. This material must possess an electrical breakdown voltage of ≤6kV. When filing and emptying procedures are in progress, contact must be maintained between each multi–layer material. Barring net or mesh, the materials that comprise the inner lining must match those used in the panels of a Type D FIBC.

Solutions for Dissipating Static Bulk Bags

It only takes a small current with high potential to ruin an IC. When static discharge occurs amidst the process of a semiconductor, the damage can be tremendous and costly. It only takes one wrong move by an untrained set of hands to ruin a chip. If an ungrounded IC is carried through a field of electrostatic, a landfill could result. Further damage could occur if the surfaces of the parts within the field attract dust and resultant contamination.

To prevent such charges, more advanced solutions are required than non–insulating material. After all, contact between parts and conductive material can result in discharge and a leakage of lead current.

At the same time, insulative material is unable to dissipate harmful charges. If a chip makes contact with material of that sort, the charge could end up destroying the chip. Meanwhile, the semiconductor is capable of generating charges of a high–static nature.

A charge of this nature has the potential to split the electrical charges on a semiconducting device. When said device makes contact or even comes into proximity with a metal object, the discharge of split charges can be disastrous.

The solution to such problems has been found in the form of electrostatic dissipative material, the category for which includes a few different types of plastic. Even though insulative qualities have always been present in most plastics, manufacturers have worked to improve the versatility of such material in recent times.

For sensitive components to be carried or transferred in an electrostatic environment, the handling materials must be dissipative and capable of discharging static electricity. Conductive plastics are capable of meeting these demands. It’s this combination of qualities that have made such materials optimal for use in FIBC Type C and D bulk bags.

CROHMIQ Packaging Material for Type D Bulk Bags

CROHMIQ is the most popular material used for Type D bulk bags. With its ungrounded antistatic qualities, the safety of CROHMIQ is unmatched among FIBC Type D protective materials. Millions of CROHMIQ FIBCs have been utilized in some of the most toxic, flammable settings.

With its advanced technology, CROHMIQ Type D bulk bags are even safer than Type C FIBCs because, unlike with the latter, there’s no risk of error on the part of handlers. These are just some of the reasons why companies around the world have converted Type B and Type C FIBCs into CROHMIQ Type D bulk bags.

CROHMIQ FIBCs can be used again following a wet or dry refurbishment. Thanks to the permanent nature of the material’s antistatic qualities, the dissipative benefits of CROHMIQ never degrade or fade away, even when a bag is being reconditioned. This stands in marked contrast to conventional Type D bulk bags, which can lose their performance capabilities under the process of wet reconditioning.

The CROHMIQ Type D bulk bag doesn’t even necessitate grounding, though the material can be grounded if such a measure is required for an operation. The antistatic material that comprises CROHMIQ is safe for food contact according to FDA and EU standards.

The material used for CROHMIQ Type D bulk bags is recurrently tested at some of the world’s most high–tech facilities. After nearly two decades, tests have proven over and over again that CROHMIQ remains that safest of all FIBC paneling materials. With its full fulfillment of universal safety and antistatic standards, CROHMIQ is set to be the leading material for FIBC Type D classification bags going forward.

Type C and Type D FIBCs from Midwestern Bag

At Midwestern Bag we sell FIBC Type C and Type D containers for a variety of purposes. With a quarter century of experience in the bulk bag industry, our team sells bulk bags of the finest quality. Situated in Ankeny, Iowa, our central U.S. location allows us to fulfill orders to all corners of the nation with speed and quality assurance.

Here at Midwestern Bag, our team is ready to help you with answers to FIBC questions. Contact us between Monday and Friday, 8:00 am to 5:00 pm CST for further information.

Copyright © 2024 Midwestern Bag. All Rights Reserved.

Copyright © 2024 Midwestern Bag. All Rights Reserved.