What Are UN-Approved FIBCs?

UN-approved FIBCs are designed to transport hazardous materials. These bulk bags have been tested and certified as being appropriate for carrying dry, flowing materials. These bags will feature the UN logo along with a code that provides more specific information about what the contents of the bulk bag will be. For example, solids are marked with an uppercase “S” in the code, while the code for liquid features the hydrostatic test pressure in kPA.

If your bulk bags do not feature this UN permanent marking and code, they may still be high-quality bulk bags, but they are not UN-certified bulk bags.

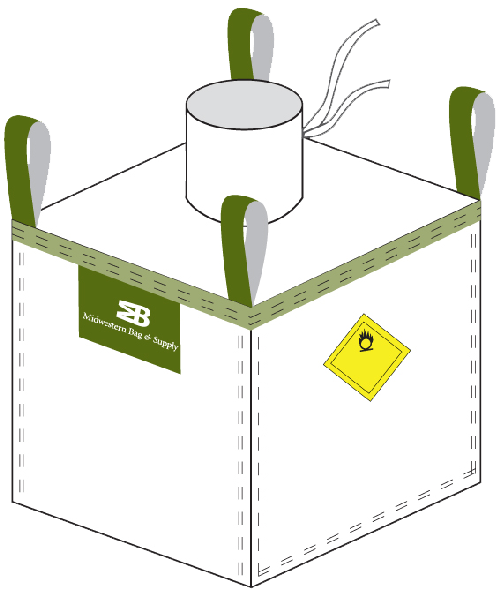

UN Bulk Bags for Hazardous Material

Companies that carry, lift or store hazardous materials need high-quality, durable bulk bags that they can rely on to hold their materials safely. As a UN FIBC supplier, Midwestern Bag & Supply is that company for your business. Our hazardous material FIBCs receive UN certification because we craft them with the best possible materials this industry has to offer and with every possible safety issue in mind. We carefully craft these bags to protect you against spills, leaks and contamination.

We know you take your business and your responsibility to transport or store hazardous materials very seriously. Let us show you the level of our commitment to excellence and perfection in the bulk bag industry with our UN-certified hazmat bulk bags.

Midwestern Bag & Supply Is a Leading UN Bulk Bags Supplier

Midwestern Bag & Supply manufactures FIBCs that safely store and transport hazardous materials for packaging groups II and III. When you choose us for your UN FIBCs, you’ll find that:

- We use the strongest virgin polypropylene in every FIBC. Tightly woven virgin polypropylene resists degradation and prevents contents from It’s even suitable for transporting and storing the finest powders. Our UN FIBCs meet stringent DOT standards and are constructed to a 6:1 Safety Factor.

- UN bulk bags from Midwestern Bag & Supply meet or exceed stringent tests prior to shipping. We drop, stack, topple, right and tear every bag to assure your order meets or exceeds the highest quality standards. We also design our bags for maximum capacity and flexibility, so you’ll get more for your money. Our bags retain shape and stay strong, even during prolonged storage, lifts and transport.

- We manufacture several UN bulk bags for our inventory but can create a design that’s built for your specific needs. Talk to a Midwestern Bag & Supply sales representative to find out what storage containers are right for you, or ask about our free bag diagnostics program. We can design and manufacture a bag that meets your precise requirements.

- Our hazardous material bulk bags come in whatever size you require for your business. From small bags to super-sized sacks, we can customize the size of your bags to suit your needs while still providing you with the same UN-certified high-quality and level of safety for every bag.

- We offer unparalleled customer support for all of our products and services. If you need to know anything at all about our UN-approved FIBCs, call us at 877-311-3422 right away, and can answer any questions or handle any concerns you may have.

UN Certified Hazmat Bulk Bag Supplier

Whether you have a local business, you operate in another state or even if you operate in another country, Midwestern Bag & Supply has the products and capacity to meet all of your hazmat bulk bag needs.

We service both large and small companies all over the world with our high-quality bags. Those companies know that Midwestern Bag & Supply is the company you can always count on to provide bags for you to responsibly and safely transport, lift and store all of your most hazardous materials. Remember our motto: Excellence is our standard, and perfection is our goal.

- Midwestern Bag & Supply manufactures every bulk bag we make in a certified clean room, and we inspect every order before it leaves our facility. Because our trained employees care about the quality of your product, you can trust us to protect your reputation.

- The industry’s leading safety and quality organizations certify our bulk bags for a wide range of uses. Some of the certifications we’ve earned include FSSC 22000, BRC (GFSI recognized), AIB, HACCP and ISO 9001:2008.

- We’ll stock and release your order. You can buy hazmat bulk bags, and we can store your bags until you need them. Just let us know when you’re ready, and we’ll ship them — saving you storage space.

UN-Certified FIBC Testing Procedures

We rigorously test our UN-Approved FIBCs to make sure they always meet the high standards that UN-certification demands. We want you to be completely confident that every bulk bag we send you for your hazardous materials is going to perform just as you expect it to. When it comes to hazardous materials, we understand that there is no margin for error, and our testing procedures reflect that.

Our UN-Certified bags include a 6:1 Safety Factor and meets stringent DOT standards. Testing procedures as follows:

Drop Test: FIBC/bulk bag is lifted and dropped at a specified height. Drop heights are determined by packaging group, with standards at: I at 5.9 feet; II at 3.9 feet; and III at 2.6 feet. Some larger bags, or those carrying heavier materials, will have slightly smaller drop heights.

Stacking Test: FIBC/bulk bag is stacked on a number of bags. Each bag will need to be at least 95% full and then will be placed on a solid, flat surface. They will be tested with a uniformly distributed load for at least five minutes. If you’re using the FIBC in conjunction with composite materials, crates or other equipment, it may need to be tested in conjunction with the bulk bags. Packaging will be tested using a dynamic compression testing machine or similar apparatus to ensure that the entire FBIC is functioning properly.

Top Lift Test: FIBC/bulk bag is tested at 6x the SWL. The load must be evenly distributed and the lift test will clear the floor and maintain the lift position for at least five minutes. Flexible IBCs will need to be 95% full with a material that is representative of the product being shipped.

Topple Test: FIBC/bulk bag is toppled at a specified height. Heights vary from 5.9 feet to 2.6 feet, based on the Packaging Group, and the bag will need to be toppled onto any part of its top onto a smooth, non-resilient surface. To pass the test, the bag will need to be 95% full and have no loss of contents from the topple. Slight discharge from stitch holes and other intended areas is not an immediate failure, as long as leakage doesn’t continue.

Righting Test: The toppled FIBC/bulk bag is lifted by only two corner lifting loops. Lifting occurs from the top or the side on a bag that’s at least 95% full. The lift speed will be 0.33 feet per second from its side to an upright position, clear of the floor, by one or two lifting devices. Bags pass this test when there is no damage to the FIBC or the lifting device itself.

Tear Test: Specified cut is applied to the middle of the FIBC / bulk bag and must hold 2x the SWL. In this test, the bag will be completely penetrated with a cut made at a 45° angle to the principal axis, halfway between the bottom surface and the top level of the contents. Passing this test requires a sturdy bag that prevents the cut from propagating more than 25% of the original cut length.

Regulations for UN Bulk Bags

Title 49 Code of Federal Regulations

Transportation is one of the main focuses in the U.S. Code of Federal Regulations and it is governed principally in Title 49, as this is issued by the Department of Transportation, Department of Homeland Security and other federal agencies governing hazardous material handling and movement. There are multiple specifications that cover flexible bulk UN containers.

Beyond standard packaging requirements, §173.24b presents a variety of additional general requirements for bulk packaging. These include:

- Liquids and liquefied gases must be so loaded that the outage is at least 5% for materials deemed poisonous by inhalation, or at least 1% for all other materials, measured by the total capacity of the container, such as the cargo tank. Tank cars and similar compartment units are allowed to include their dome capacity.

- Hazardous materials cannot be directly loaded into the dome of a tank car, and additional vacant space will be required if the dome of the tank car does not provide sufficient outage.

When using bulk packaging in tank cars, specific temperature caps must be adhered to, based on what is being transported and in what situation:

- 46° C (115° F) for a non-insulated tank.

- 41° C (105° F) for an insulated tank.

- 43° C (110° F) for a tank car that has a thermal protection system. The system needs to incorporate a metal jacket that provides an overall thermal conductance at 15.5° C (60° F) of no more than 10.22 kilojoules per hour per square meter per degree Celsius.

A few other key regulations for you to consider include:

- 178.1020: The use of flexible bulk containers for the transport of hazardous materials is permitted for a period of time not to exceed two years from the date of manufacture of the flexible bulk containers.

- 178.1015 (a): Each flexible bulk container must be sift-proof and completely closed during transport to prevent the release of contents, and waterproof.

- 178.1015 (b:1-2): Flexible bulk containers used with hazardous materials must not be affected or weakened by those materials. The bags cannot cause new dangers, such as creating a catalyzing reaction with the hazardous materials.

- 178.1015 (b:3): UN bags cannot be permeable — so hazardous materials cannot leak or otherwise vacate to cause a new hazard. Filling and discharge devices must be properly secured during handling and shipping. Ventilation devices must be fitted to any bulk containers if the hazardous material could cause an unsafe buildup of gases.

UN Recommendations on the Transport of Dangerous Goods

The UN Model Regulations also provide guidance on how to use bulk packaging for the shipment of dangerous or hazardous goods. Many of these guidelines will follow the same mode of thought as the Title 49 requirements, such as not combining shipments of hazardous materials that may react, whether in the bag or with the bag itself.

It makes many notations that your shipping partners, and those throughout your supply chain, will appreciate. This includes Section 4.1.1.10, which notes that liquids shall be filled only into packaging, including these FIBCs, that have an appropriate resistance to the internal pressure that is likely to occur during normal transportation conditions.

One of the most important sections for our customers is 4.1.2.1: when IBCs are used for the transport of liquids with a flash point of 60° C or lower, or of powders liable to dust explosion, measures shall be taken to prevent dangerous electrostatic discharge. Measures can include selecting the appropriate type of container as long as it has passed the relevant testing before being put into service.

These are just a small set of the relevant codes, regulations and statues that your equipment must adhere to if you’re shipping hazardous or other reactive materials. No website can do proper justice to preparing your team or ensuring that everything is being appropriately handled.

We recommend that you reach out right away to learn more about what requirements you’ll need to adhere to, based on your materials, shipping methods and lanes, volumes and more.

UN FIBC Markings

The UN has developed a code to help those handling hazardous material bulk bags know at a glance what materials are in those bags. These markings appear clearly on the exterior of the bag for the safety of all those who come in contact with these bags. It will be important for you to know what each of these visual hazardous material symbols mean. They are:

- Class 4.1: Indicates flammable solids, desensitized explosives and self-reactive substances

- Class 4.2: Materials have the capacity to spontaneously combust

- Class 4.3: Substances within cannot encounter water without expending a flammable gas

- Class 5.1: Oxidizing chemicals are in this container

- Class 5.2: Organic peroxides exist inside

- Class 6.1: This indicates toxic materials

- Class 8: If you see this symbol, you will know there corrosive substances inside

- Class 9: The bag contains dangerous materials and articles of an uncategorized, miscellaneous nature

The above symbols are not the only information UN bags use to outline the attributes of contained products. These bags allow users to track the specific materials, origin, manufacturer, maximum gross mass and other important qualities through an additional labeling system with components that correspond to specific information. The bag label has numbers, symbols and letters that each refer to a quality the bag handler needs to know in order to determine safe handling practices. Below is what you will see when you check out the UN ID on a container:

A. The United Nations Packaging Logo will appear on every label no matter what the following information entails. 178.503(e)(1)(ii)

B. The code number in this section will let you know the FIBC design type. 178.702(a)

C. A capital letter will identify what performance standard this bag’s design type has been tested under with success.

D. Next listed are the month and year the container was manufactured, always presented in numerals.

E. Indicated here is the country that authorized the allocation of the mark. 178.503(e)(1)(ii)

F. This section gives the name and address or symbol of the container manufacturer or approval agency that certified compliance with subpart N and O of 178.

G. Section G lets you know, in kilograms, the stacking test load of the container.

H. The maximum gross mass each container can hold is listed last.

At Midwestern Bag and Supply, it’s our priority that you stay safe and follow legal guidelines while handling any type of materials, including hazardous products of any variety. Contact us online or by phone, email or fax if you need more information about how to mark a UN FIBC or want to place an order.

Contact Midwestern Bag & Supply – Your UN Bulk Bags Supplier

Midwestern Bag & Supply delivers in-stock and custom orders promptly.

Call a sales representative today at 877-311-3422.

Copyright © 2024 Midwestern Bag. All Rights Reserved.

Copyright © 2024 Midwestern Bag. All Rights Reserved.